marketing@harikrushna.com - +91-6357101667

- Send SMS Send Email

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Harikrushna Machines |

| Material | Stainless Steel |

| Color | Silver |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Condition

New

Automatic Grade

Automatic

Specialities

Corrosion Resistant

Type

Automatic Cap Sealing Machine

Country of Origin

India

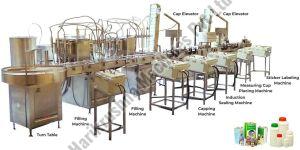

Automatic Rotary ROPP Cap Sealing Machine

The Automatic Rotary ROPP Cap Sealing Machine consists of a main structure, product transmission belt with an adjustable guide, in-feed screw, star plate, sealing heads, vibratory bowl for caps, cap delivery chute, product's height adjustment screw, safety acrylic cover (OPTIONAL), electrical panel, motor, sensors & AC drive.

Key Features

- The Ropp Cap Machine is manufactured or developed accordance with GMP standards.

- Rigid vibration free construction for trouble free performance.

- SS Elegantly matt finished body.

- Electro less Nickle plating or MS powder coating of all exposed parts to ensure long life and resistance against corrosion.

- No bottle no cap arrangement.

- Single motor synchronizes conveyor, star wheel, & platform turret.

- Adjustable height of conveyor belt to align with other machine of the line.

- Sealing pressure can be varied to suit different gauges and size of caps.

- No cap in chute vibrator on & Machine Stop.

- There is a special designed vibratory bowl and chute with no cap sensors for continuous flow of the cap.

- Clutch Overload – Machine Stop.

- Low noise level, low power consumptions.

- Spring loaded pin in the center of capping die. (ROPP)

- Manually adjustable (increase & decrease) mechanical torque (magnetic clutch) heads system. (ROPP Capping)

- Fix set pin for star plate & in-feed screw.

- Self-lubricating UHMW- PE guide profile for low friction wears surface, smooth and noiseless conveying.

- Star wheel & Guide MOC: UHMW–NYLON.

Looking for "Automatic Rotary ROPP Cap Sealing Machine" ?

Unit